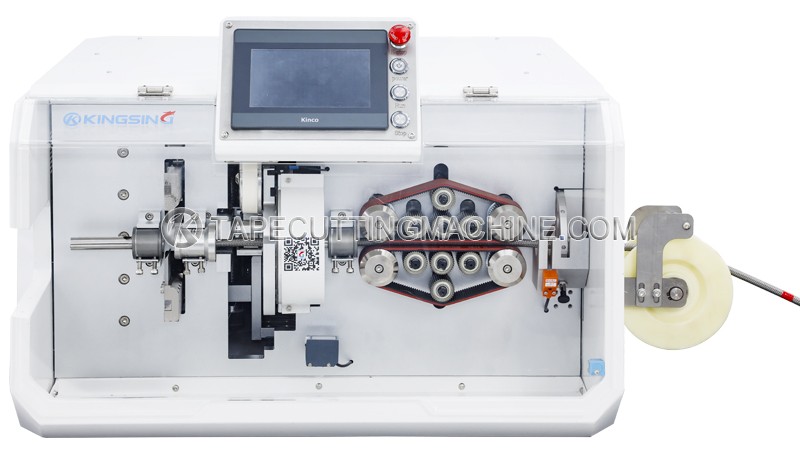

An automatic winding and cutting machine is a device used for processing wires, cables, flat conductors, flexible copper bars, sheathing pipes, and various PVC hoses. It can automatically cut, strip, and wrap adhesive tapes, masking paper, or other self-adhesive materials at specified positions.

Here are some common features and characteristics:

Automatic Cutting: The machine can automatically cut materials to the set length, improving processing efficiency and accuracy.

Automatic Winding: It can automatically wind adhesive tapes or other sticky materials at designated positions to

achieve insulation or markingpurposes.

Efficient Production: Through automated operations, it reduces manual intervention, improving production efficiency, and lowering labor costs.

Precise Positioning: The design is precise, ensuring that materials are accurately positioned and processed during production.

Pipe Diameter: Ф9~Ф20mm (depends on the pipe material)

Tape Specification: Width: Max. 20mm ID: Ф32~76mm OD: 110mm (customized)

Blade Type: Cold blade

Cutting Length: Max. 1000m

Cutting Accuracy: ± 0.5+L x 0.002mm (L=cutting length)

Speed: 600~800 pcs/hour (Depends on cutting length and wrapping turns)

Power Supply: 220V / 50Hz

Power Rating: 1000W

Program Memory: Max.100 groups of programs

Customized Function: Defective tube detecting and cutting

Air Pressure: 0.5~0.7MPa (Must be clean, dry and stable compressed air)

Dimensions (L×W×H): 870*760*600mm (34.25*29.92*23.62in) (Protrusions are not contained)

Net Weight: 174Kg (383.60lbs)

English

English